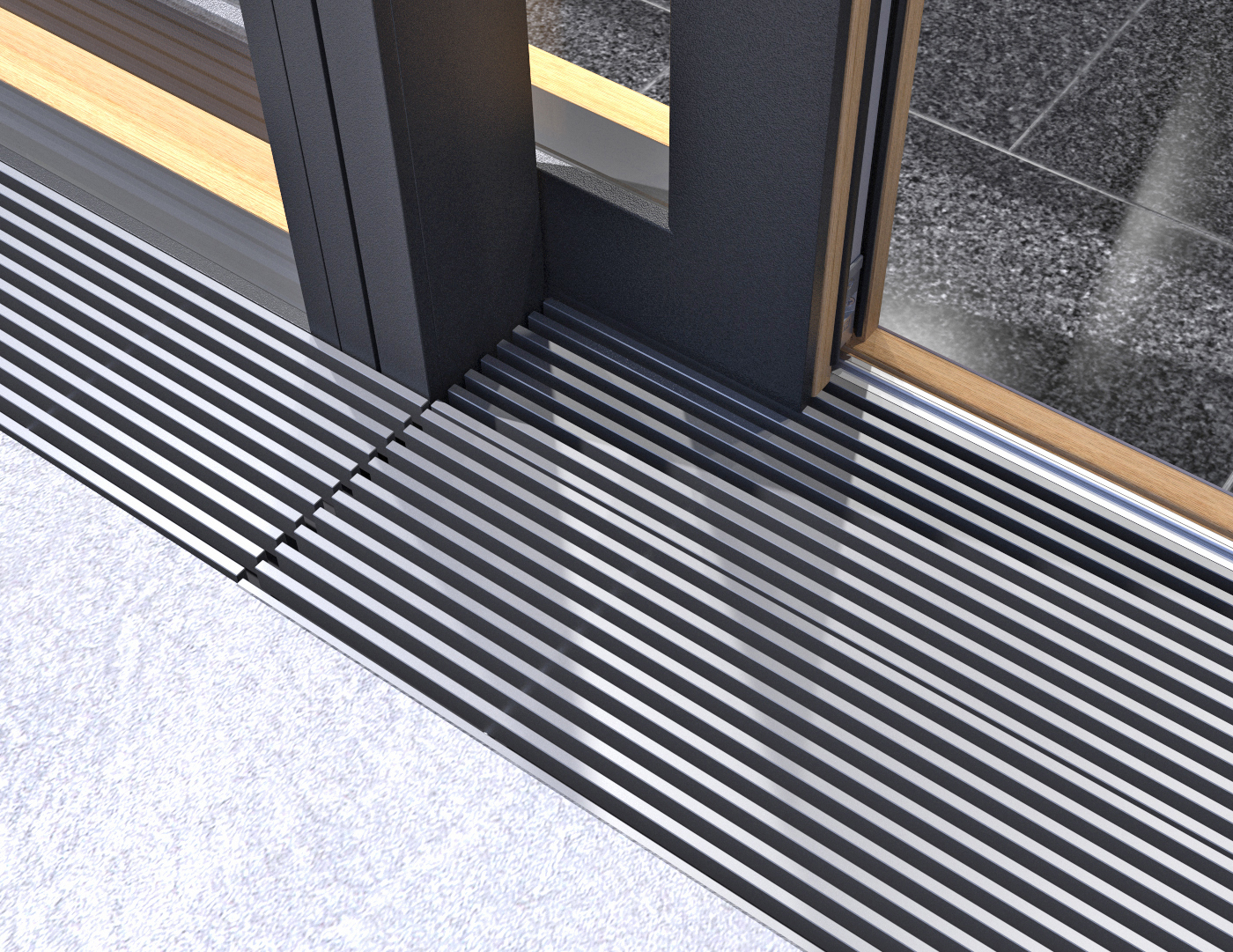

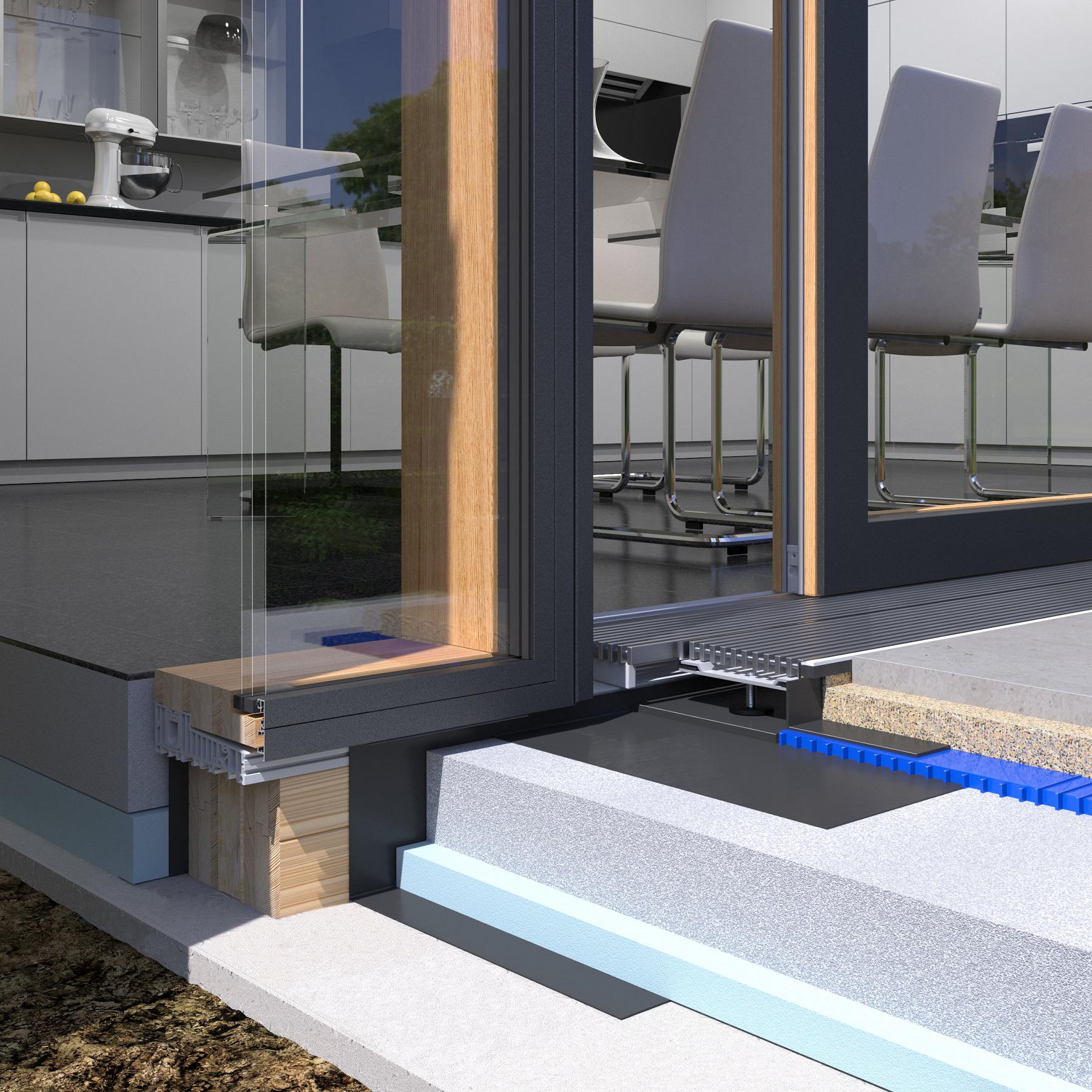

- Water cannot penetrate from outside due to sophisticated drainage system

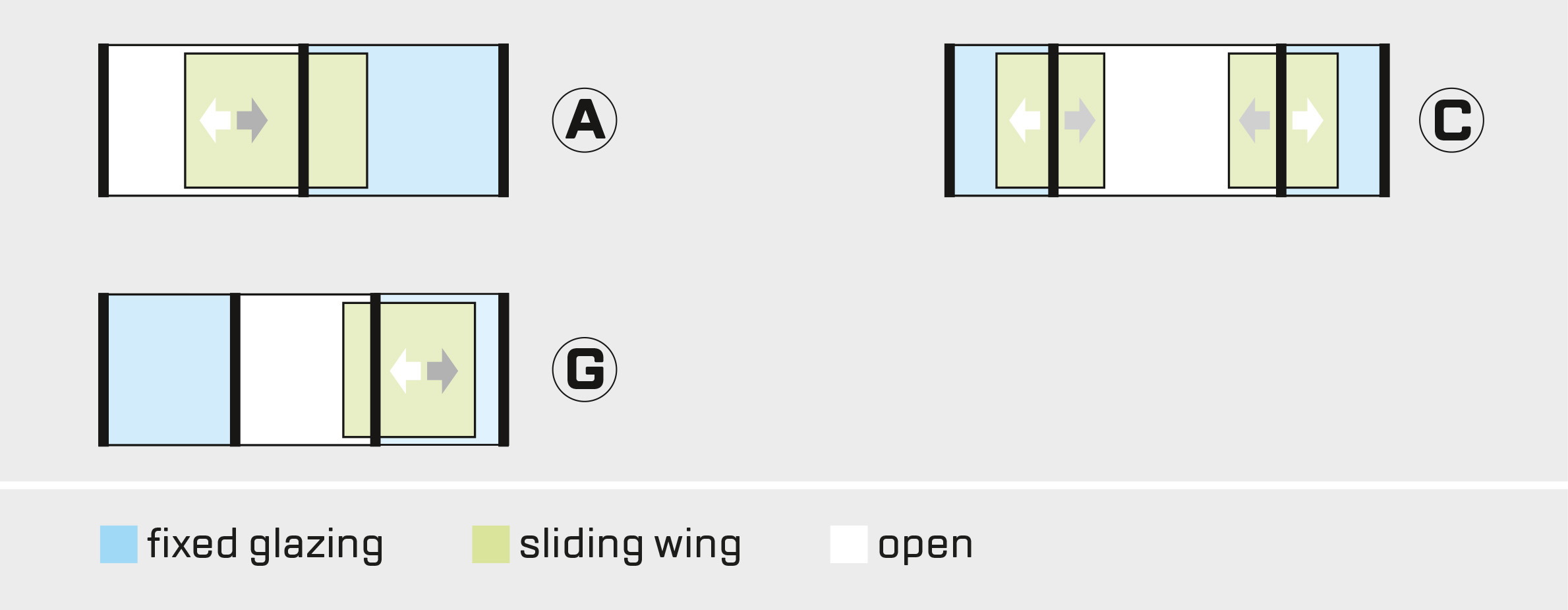

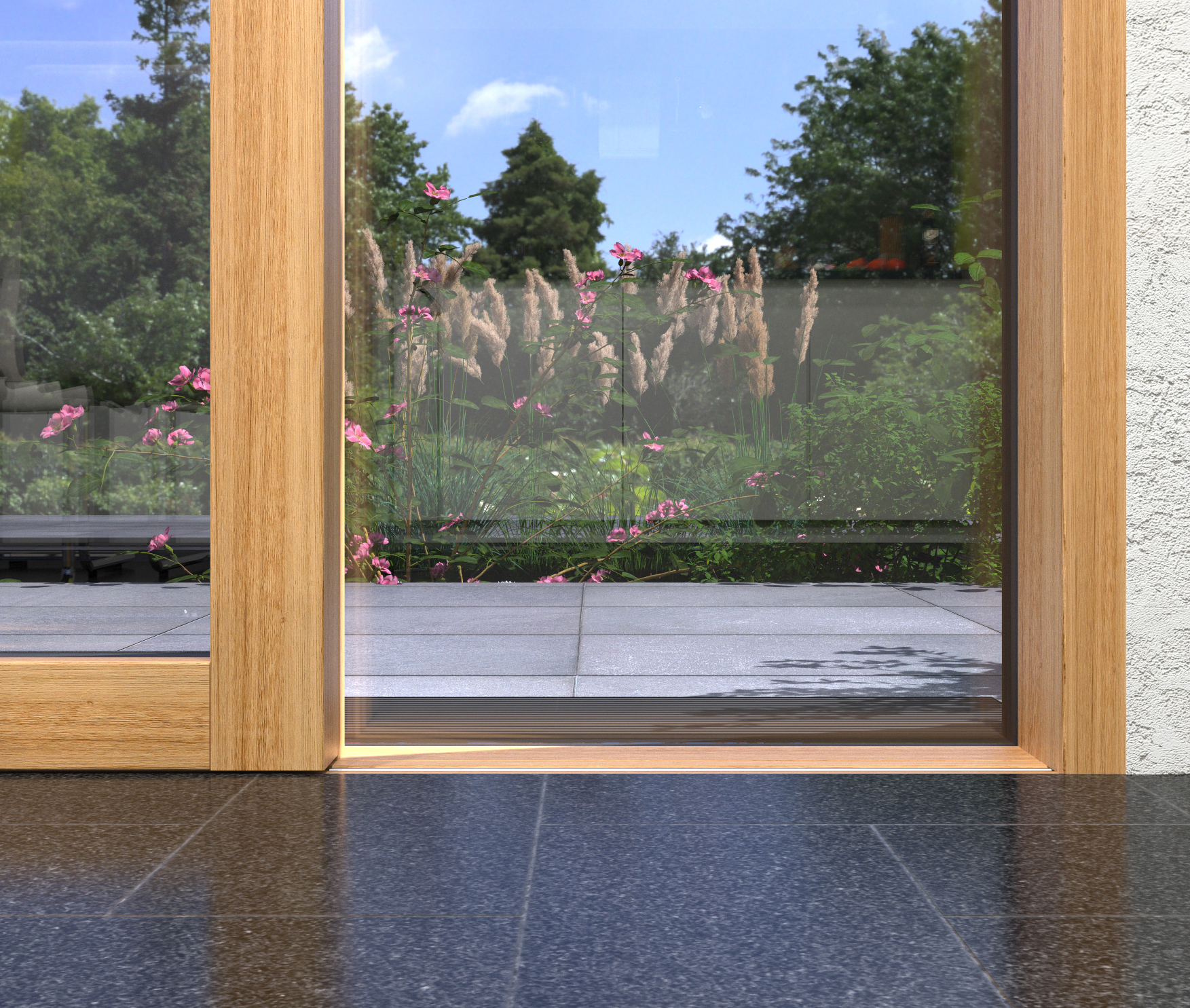

- Even more light due to maximum possible floor-to-ceiling glazing of the fixed element

- Extravagant look from the inside and outside

- Woods and surface finishes can be chosen individually

- High soundproofing, insulation and waterproofing values due to ingenious all-round sealing system

- Burglar-proof thanks to additional anti snap security devices between the fixed element and sliding sash as well as optional fitting upgrade with steel swivel hook

- Smooth and quiet running – even with heavy elements

- Safe to operate

- Extremely sturdy construction – functionally reliable and durable as a result

- Accessible flush threshold | zero barrier / threshold height 0 mm - thermally separated

- Floor-to-ceiling glazing without visible frame for fixed glass elements

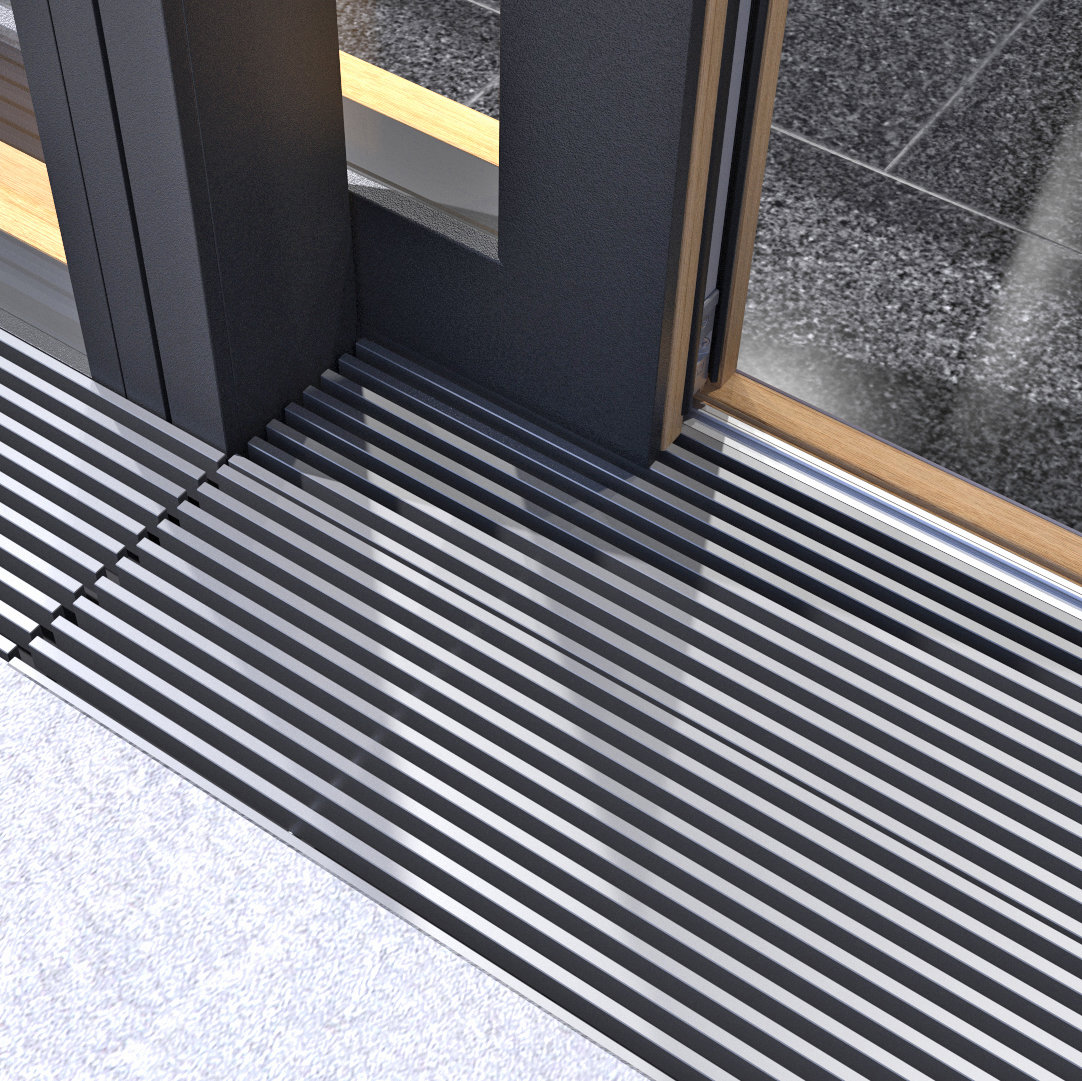

- Drainage grate system – with inner grate in the passage and outer circumferential grate – drains the water downwards in a controlled manner

- Drainage mat (blue) drains the water in a controlled manner and the sealing membrane is welded waterproof

- Individual layered patio structure

Drainage system absolutely essential with the HST 3.0 system!

The DÖPFNER scope of delivery includes the inner drainage grate in the sliding elements’ passage.

The external, circumferential drainage grate system and the individual patio structure are designed, supplied and installed by external suppliers!

Zero-barrier solutions often need to be very individually adapted to a construction project. Often, no clearly applicable DIN/EN standards (recognized rules of construction engineering) exist for special situations. Technical innovation regularly progresses faster than the 5 to 10-year updating cycle for common regulations. Existing standards prescribe a threshold height of 15 cm, which is of course by no means “accessible”!

Customized design versions are referred to as SPECIAL CONSTRUCTIONS in construction practice: Components and/or services are planned and implemented with the utmost care according to the current state of construction engineering, but there is no standard form of execution as per DIN/EN.

This means that customized solutions for the property are agreed between the contractor and the client. Information and clarification about the special construction are provided by the contractor and need to be contractually agreed in writing between owner builder, planner and contractor.

To guarantee permanent waterproofing, the patio structure must be designed in such a way that rainwater is drained off in a controlled manner via a drainage system. The national standards regarding exterior drainage (beyond Döpfner components) must be complied with.

In the event of non-compliance, the DÖPFNER warranty does not apply to these components!